magtec GmbH

Bahnstrasse 73

67518 Ellerstadt, DE

coating solutions

coating solutions

We do coatings on customer-supplied windows and substrates with predefined sheet resistance.

Coatings for Quantum optical devices

We are specialist in coatings of high sophisticated prototypes like parts of quantum optical devices. We do coatings of flat or 3D parts with e.g. Gold, Copper or Aluminum.

Indium Tin Oxide (ITO) Coating

ITO coated glass offers high visible light transmission, virtual neutral colour and low electrical resistance.

Due to these astonishing properties of ITO coatings, substrates for optics, displays and windows can be provided with transparent layers of high electrical conductivity.

One typical application is the coating of displays and components for OLED-technology.

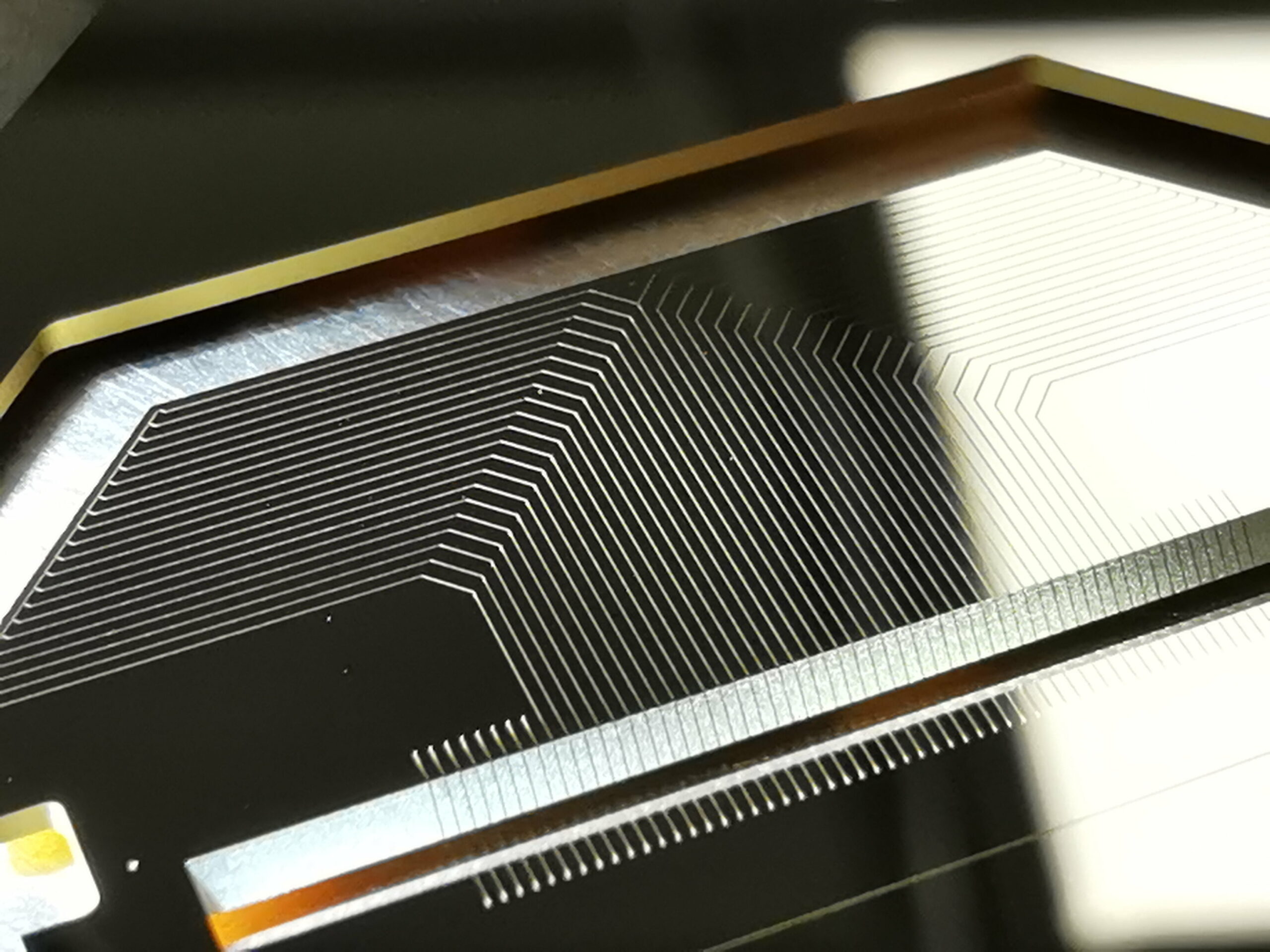

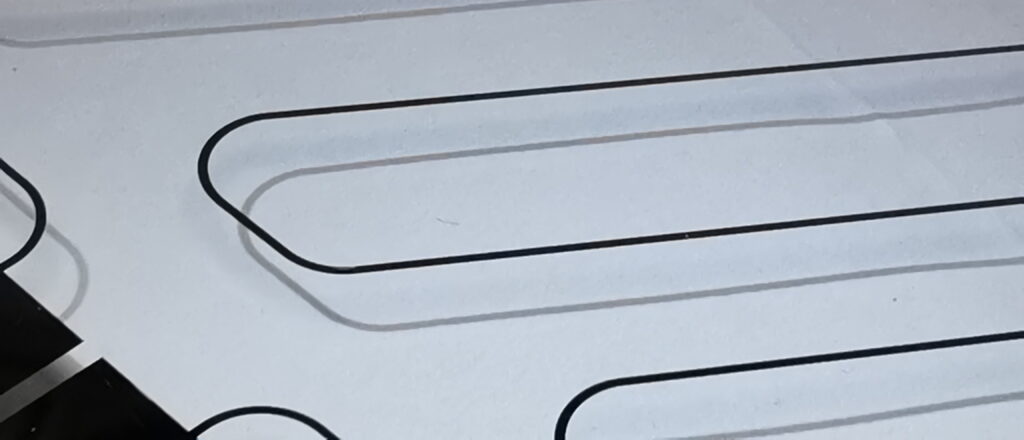

Another application is the coating of windows for high-end optical systems and measurement equipment. By etching a previously applied ITO coating, windows can be provided with transparent heating lines that prevent fogging of the optics in the field.

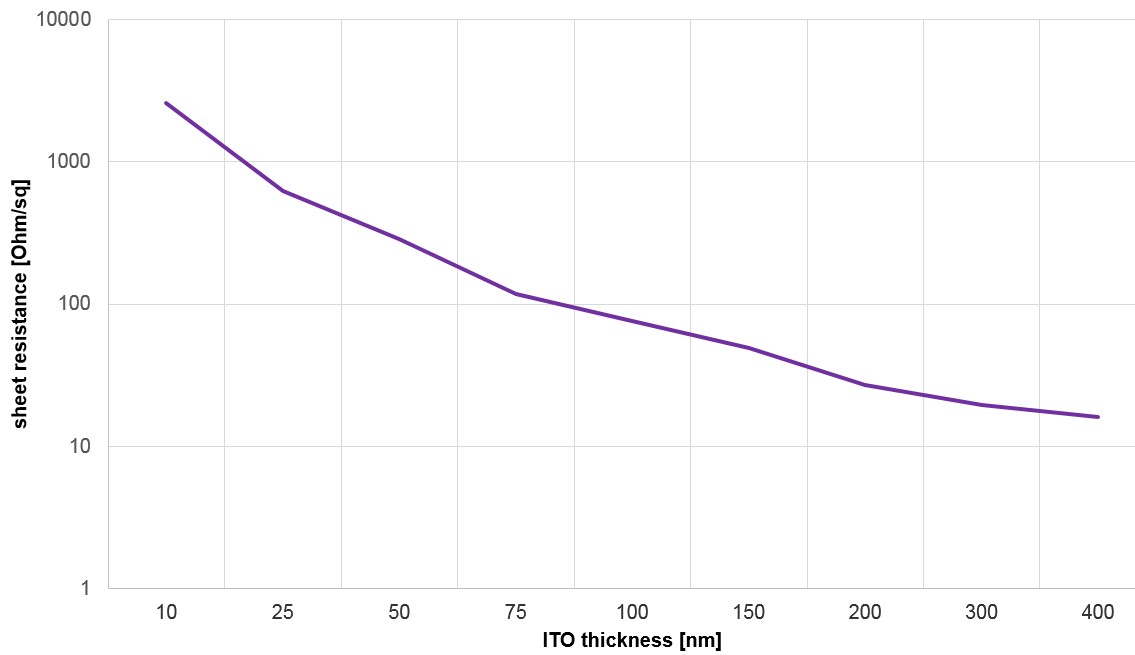

The following graph shows the dependency between sheet resistance and layer thickness of a ITO coating done at room temperature (without annealing):

Another application is the ITO coating of so-called Pockel cells, which are used in laser technology. The conductive ITO coating ensures that an electric field in a crystal can be switched on and off, which in turn ensures the propagation of the laser light. The combination of the ITO coating with an anti-reflective coating ensures that the laser light is hardly attenuated as it passes through the switchable crystal.

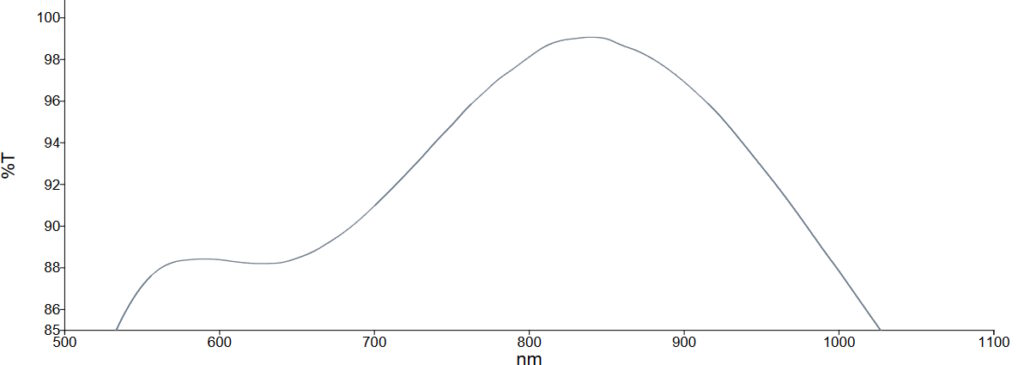

The following graphic shows the transmission shortness of such a combined ITO/anti-reflective coating: