magtec GmbH

Bahnstrasse 73

67518 Ellerstadt, DE

coating solutions

coating solutions

B4C coatings for neutron detectors

We are one of few companies producing enriched Boron-Carbide coatings for neutron detectors in radiation protection and basic research.

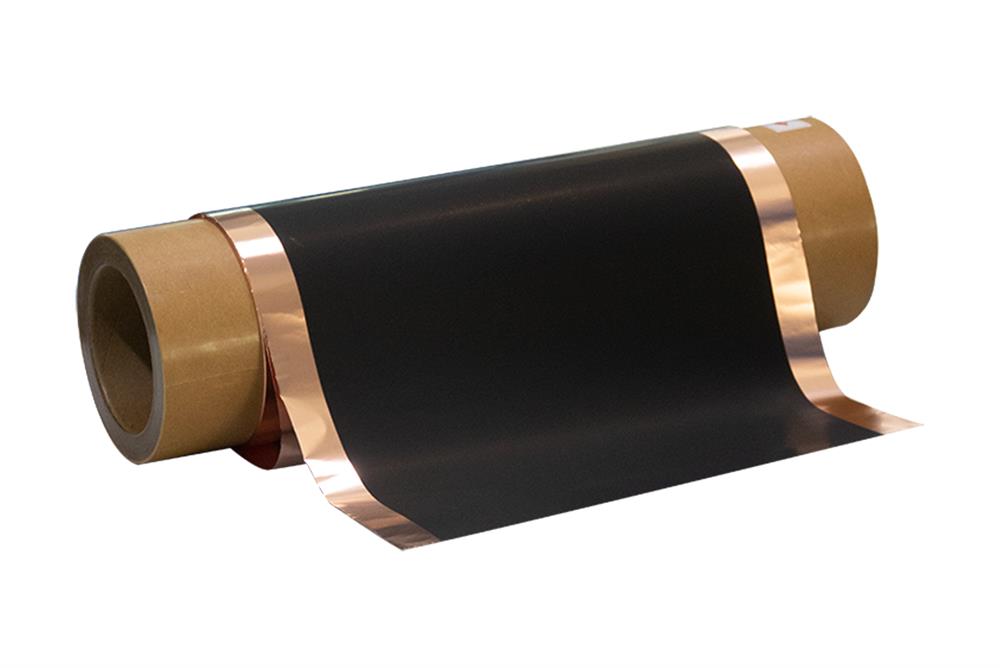

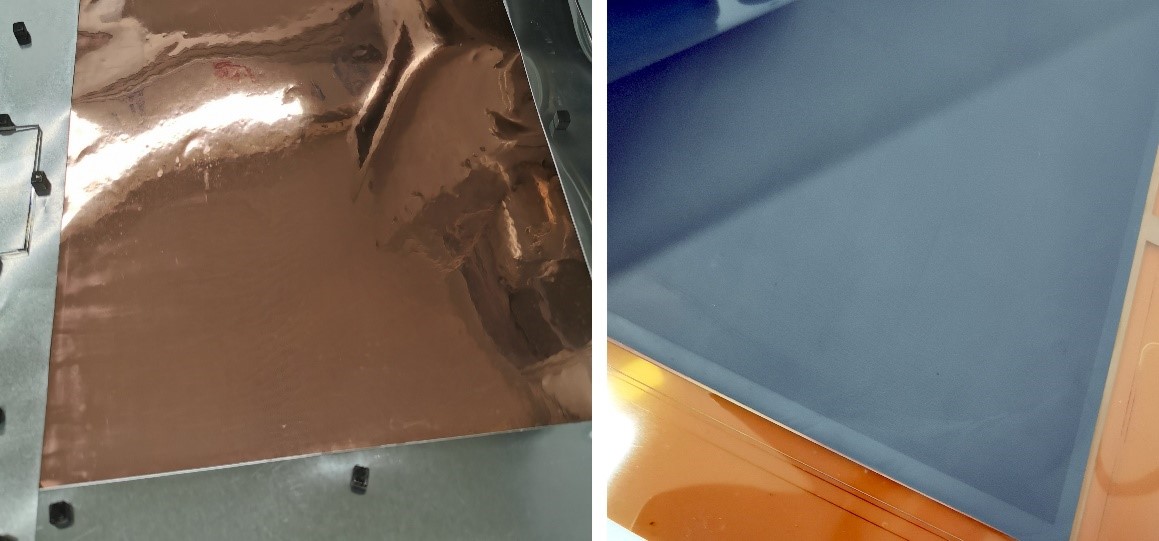

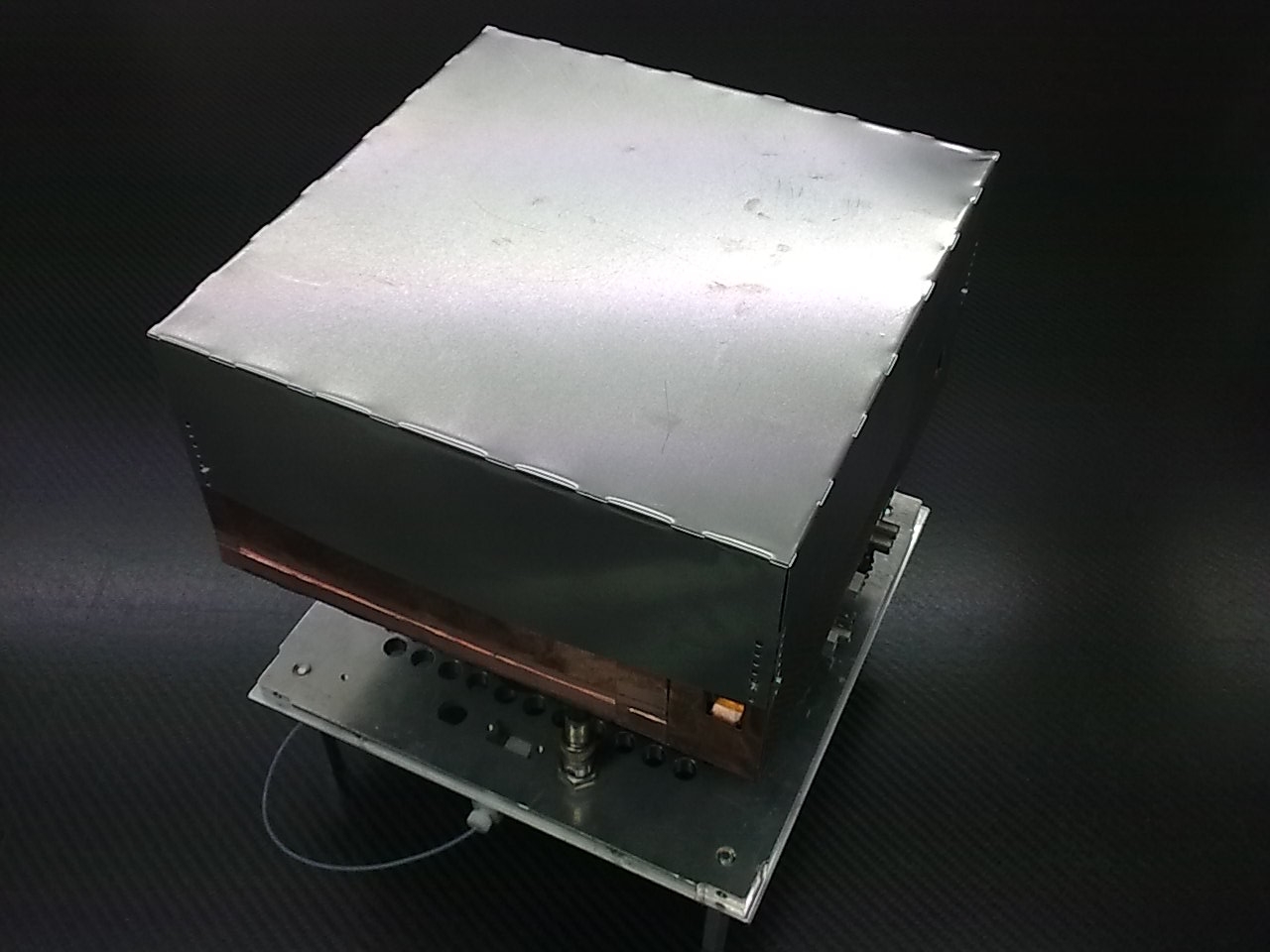

With our magnetron-deposition technique we coat GEM-folies (see below) and one or double side of aluminium or copper foils with sizes up to 400 x 1200 mm and up to 2 μm thicknesses.

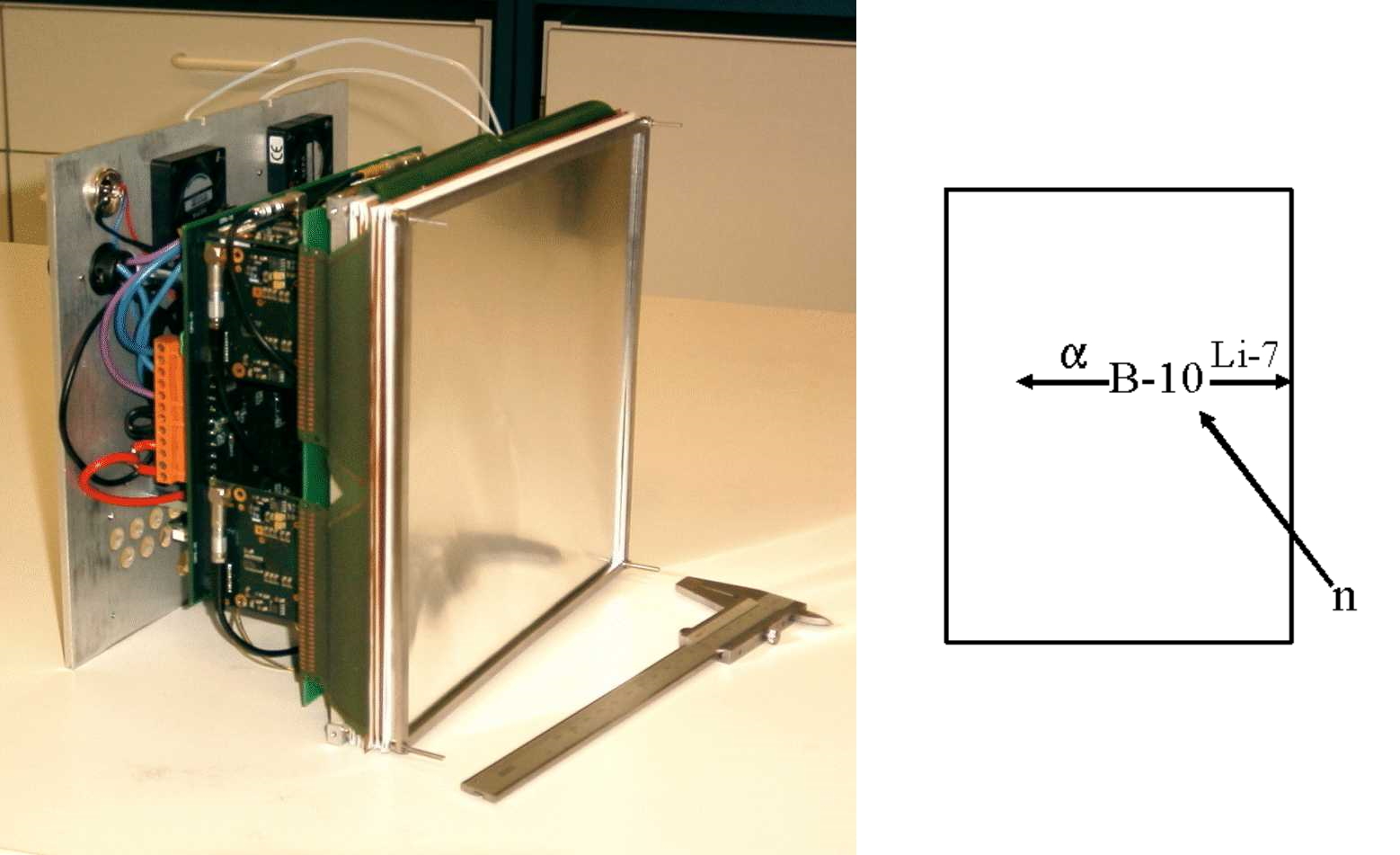

The enriched 10B from boron-carbide targets works as neutrons converter: Neutrons pass through a coating layer of enriched boron-10 and are converted into a lithium-7 atom and an alpha particle (helium nuclei). The charged alpha particle can then be measured with standard techniques.

We are always in close contact with our customers and partners. Cooperations with partners in research and development companies or scientific institutes ensure that our production processes fullfill the requests of specific detectors for high end applications.

For example, in collaboration with the company CDT GmbH, Heidelberg, www.n-cdt.com, we supplied 10B4C coatings for the DREAM detector at the European Spallations Source in Lund: https://europeanspallationsource.se/instruments/dream

DREAM will be an outstanding tool for structure analysis enabling new physical and chemical research in material and nanoscience using scattered neutron diffratometry.

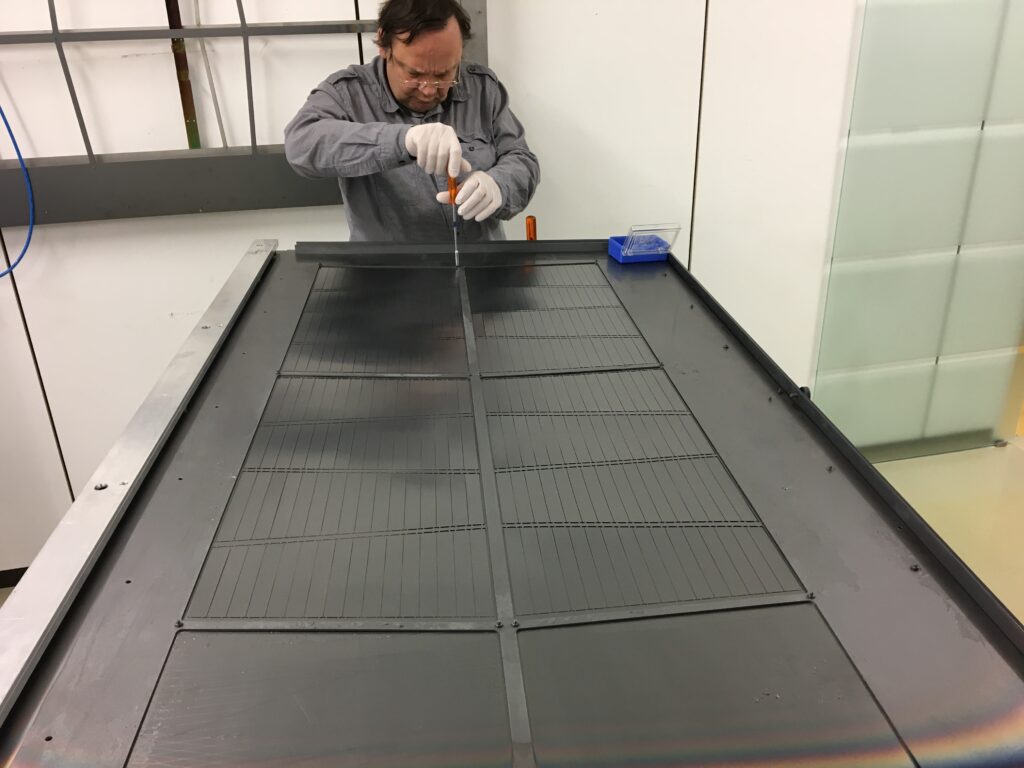

GEM (Gaseous Electron Multiplier) foils were developed at CERN, https://gdd.web.cern.ch/gem, for the big particle detectors looking for new physics. These foils combine simplicity and high technology: A capton foil is coated on both sides with copper dealing as high voltage electrodes. Several thousand holes drilled through the foils generate transparency enabling particles to pass it. Charged particles passing the holes are accelerated, ionize the detector gas and generate an avalanche of electrons which are measured by the detector.

Unfortunately, neutrons are free of electric charge and therefore can’t be manipulated and detected using the standard GEM foil detector technique.

But such foils are now available for the next generation of neutron detectors at high luminosity neutron sources (like ESS, PSI, ILL, Los Alamos, FRMII or Oak Ridge).

For the conversion of “neutral” neutrons into detectable charged particles isotopically enriched 10B4C coatings are used. After the Conversion the charged particle are measured as described.

Standard B4C is an electrically conductive material and so a short circuit between the electrodes prevent the GEM principle to work.

The development of non-conductive and enriched 10B4C coatings is the solution.

Such special coatings were developed at Magtec.

B4C coatings for X-ray mirrors

We also coat glass and silicon components with thin layers of natural B4C, which in this case serves as a reflective layer for X-rays. The coated components are then used in X-ray optics.

B4C components

We also offer workpieces for neutron physics machined out of B4C material.

Selection of publications: